Manufacturer Of Cutting Fiberglass Grating - High Quality FRP GRP Pultruded Grating – WellGrid

Manufacturer Of Cutting Fiberglass Grating - High Quality FRP GRP Pultruded Grating – WellGrid Detail:

FRP Pultruded Grating Availability

|

No. |

Type |

Thickness (mm) |

Open area (%) |

Bearing Bar Dimensions (mm) |

Center line distance |

Weight (kg/m2) |

||

|

Height |

Width top |

Wall thickness |

||||||

|

1 |

I-4010 |

25.4 |

40 |

25.4 |

15.2 |

4 |

25.4 |

18.5 |

|

2 |

I-5010 |

25.4 |

50 |

25.4 |

15.2 |

4 |

30.5 |

15.8 |

|

3 |

I-6010 |

25.4 |

60 |

25.4 |

15.2 |

4 |

38.1 |

13.1 |

|

4 |

I-4015 |

38.1 |

40 |

38.1 |

15.2 |

4 |

25.4 |

22.4 |

|

5 |

I-5015 |

38.1 |

50 |

38.1 |

15.2 |

4 |

30.5 |

19.1 |

|

6 |

I-6015 |

38.1 |

60 |

38.1 |

15.2 |

4 |

38.1 |

16.1 |

|

7 |

T-1810 |

25.4 |

18 |

25.4 |

41.2 |

4 |

50.8 |

14.0 |

|

8 |

T-3310 |

25.4 |

33 |

25.4 |

38.1 |

4 |

50.8 |

12.2 |

|

9 |

T-3810 |

25.4 |

38 |

25.4 |

38.1 |

4 |

61 |

11.2 |

|

10 |

T-3320 |

50.8 |

33 |

50.8 |

25.4 |

4 |

38.1 |

19.5 |

|

11 |

T-5020 |

50.8 |

50 |

50.8 |

25.4 |

4 |

50.8 |

15.2 |

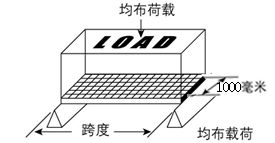

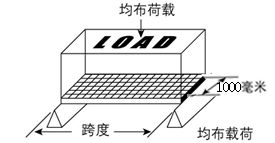

Loading Table

FRP Pultruded Grating Loading Table

Pultruded Grating T-3310

Pultruded I-5010

Pultruded Grating I-5015

Pultruded Grating T-3320

Pultruded Grating T-3310

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

0.36 |

0.86 |

1.72 |

2.58 |

3.45 |

1720 |

8600 |

|

610 |

0.79 |

1.94 |

3.89 |

5.81 |

7.75 |

1286 |

6430 |

|

914 |

2.41 |

6.01 |

– |

– |

– |

840 |

4169 |

|

1219 |

5.38 |

13.60 |

– |

– |

– |

602 |

3010 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.32 |

0.98 |

1.62 |

2.26 |

3.25 |

7520 |

37620 |

|

610 |

0.99 |

2.28 |

4.86 |

6.80 |

9.70 |

4220 |

21090 |

|

914 |

4.51 |

– |

– |

– |

– |

1830 |

9160 |

|

1219 |

– |

– |

– |

– |

– |

– |

– |

Pultruded I-5010

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

– |

2.54 |

3.59 |

4.80 |

2760 |

13800 |

|

610 |

– |

1.90 |

4.08 |

6.05 |

8.15 |

2150 |

10760 |

|

914 |

2.25 |

5.71 |

11.70 |

17.50 |

23.25 |

1436 |

7180 |

|

1219 |

5.05 |

12.70 |

25.60 |

38.20 |

50.98 |

1070 |

5368 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.50 |

1.60 |

2.65 |

3.80 |

4.57 |

12100 |

60520 |

|

610 |

1.26 |

3.13 |

5.30 |

7.37 |

10.40 |

7080 |

35430 |

|

914 |

4.56 |

13.10 |

– |

– |

– |

3140 |

15716 |

|

1219 |

13.68 |

– |

– |

– |

– |

1760 |

8809 |

Pultruded Grating I-5015

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

0.50 |

0.99 |

1.50 |

1.75 |

4370 |

21856 |

|

610 |

0.26 |

0.89 |

1.50 |

2.30 |

3.28 |

3280 |

16400 |

|

914 |

0.74 |

1.90 |

3.80 |

5.55 |

7.60 |

2116 |

10580 |

|

1219 |

1.76 |

4.18 |

8.36 |

12.46 |

16.48 |

1514 |

7570 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

1220 |

2440 |

3660 |

4880 |

|||

|

457 |

0.25 |

0.64 |

1.02 |

1.40 |

2.00 |

19100 |

95560 |

|

610 |

0.5 |

1.27 |

2.18 |

2.94 |

4.04 |

10780 |

53900 |

|

914 |

1.78 |

4.56 |

7.66 |

10.68 |

15.20 |

4630 |

23168 |

|

1219 |

4.56 |

12.60 |

– |

– |

– |

2490 |

12460 |

Pultruded Grating T-3320

|

span |

Line load (kg/m) |

Recommended max. load |

Ultimate load |

||||

|

149 |

373 |

745 |

1148 |

1490 |

|||

|

457 |

– |

– |

– |

– |

– |

– |

– |

|

610 |

– |

– |

0.51 |

0.74 |

1.06 |

3375 |

16876 |

|

914 |

– |

0.62 |

1.28 |

1.76 |

2.30 |

1500 |

7498 |

|

1219 |

0.49 |

1.27 |

2.26 |

3.52 |

4.82 |

845 |

4228 |

|

span |

Uniform load (kg/m2) |

Recommended max. load |

Ultimate load |

||||

|

488 |

976 |

2440 |

3660 |

4880 |

|||

|

457 |

– |

– |

– |

– |

– |

– |

– |

|

610 |

– |

0.38 |

0.50 |

0.64 |

1.000 |

11080 |

55400 |

|

914 |

0.52 |

1.16 |

1.90 |

2.68 |

3.80 |

7380 |

36900 |

|

1219 |

1.28 |

3.40 |

5.70 |

8.12 |

11.66 |

5570 |

27861 |

| Notes: 1, Safety factor is 5; 2, Ultimate load is the grating break load; 3, This table is only for information, resins and grating surfaces influence the grating loading property. | |||||||

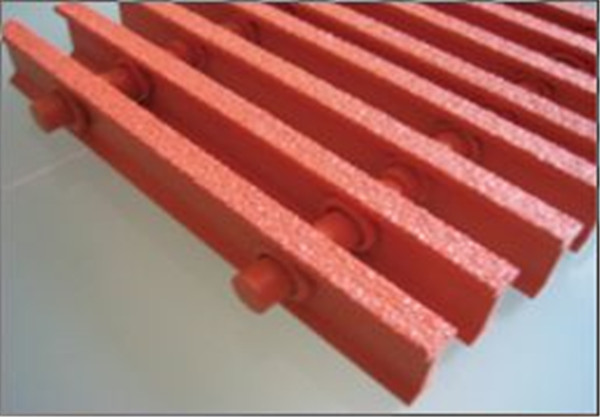

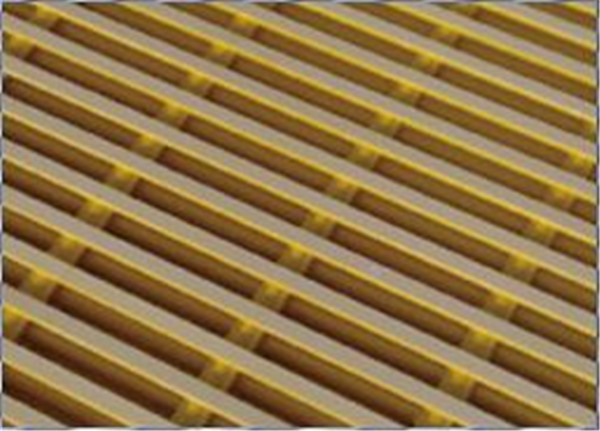

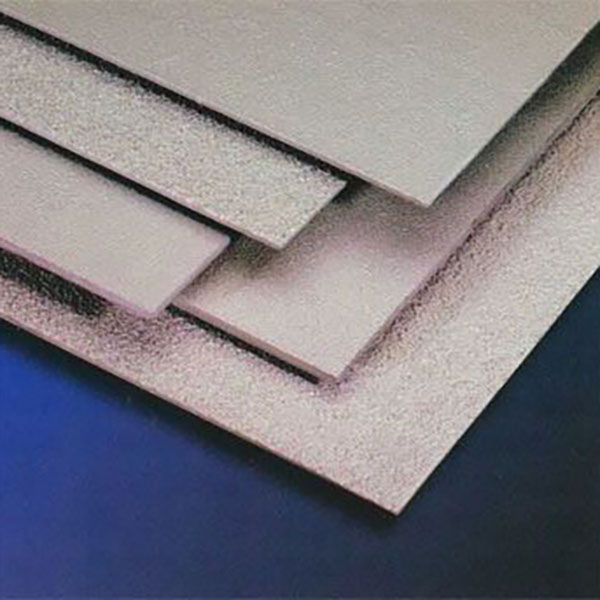

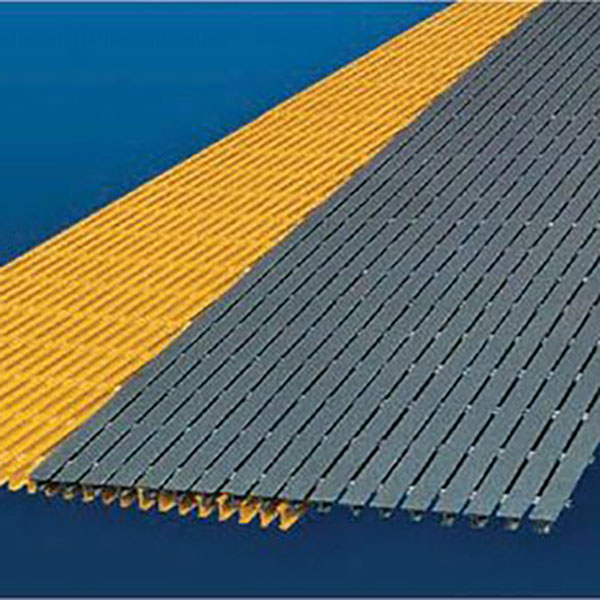

FRP Pultruded Grating Surface

|

Real |

Surface |

Service |

|

Corrugated surface (No grit) |

Anti-skid, easy clean |

|

|

Grit surface |

Anti-skid and good abrasion (The grit could be fine, middle and coarse) |

|

|

Smooth surface |

Free clean, contaminant non stay |

|

|

Chequer cover surface |

Anti-skid, easy clean, odour isolation |

|

|

Grit cover surface |

Anti-skid, good abrasion (The grit could be fine, middle and coarse), odour isolation |

Standard Resin Systems

|

ONFR |

Polyester resin system, Good corrosion resistance, Non fire resistance; |

|

OFR |

Polyester resin system, Good corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

ISOFR |

Premium grade Isophthalic Polyester resin system, excellent corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

VEFR |

Vinyl Ester resin system, Maximum corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

PHE |

Phenolic resin system, High temperature service, Low flame spread index, low smoke developed index and low toxicity. |

Chemical Properties

FRP Pultruded Grating Chemical Properties Guide:

|

Chemicals |

Concentration |

Maximum service temperature |

||

|

Vinyl ester resin |

Iso resin |

Ortho resin |

||

| Acetic acid |

50 |

82 |

30 |

20 |

| Chromic acid |

20 |

38 |

No |

No |

| Nitric acid |

5 |

70 |

48 |

25 |

| Phosphoric acid |

85 |

100 |

65 |

No |

| Sulfuric acid |

25 |

100 |

52 |

20 |

| Hydrochloric acid |

<10 |

100 |

52 |

No |

|

20 |

90 |

38 |

No |

|

|

37 |

65 |

No |

No |

|

| Hydrotropic acid |

25 |

93 |

38 |

No |

| Lactic acid |

100 |

100 |

52 |

40 |

| Benzoic acid |

All |

100 |

65 |

—— |

| Aluminum hydroxide |

All |

82 |

45 |

No |

| Aqueous ammonia |

28 |

52 |

30 |

No |

| Sodium hydroxide |

10 |

65 |

20 |

No |

|

25 |

65 |

No |

No |

|

|

50 |

70 |

No |

No |

|

| Ammonium sulfate |

All |

100 |

60 |

50 |

| Ammonium chloride |

All |

100 |

82 |

60 |

| Ammonium bicarbonate |

All |

52 |

No |

No |

| Copper chloride |

All |

100 |

65 |

60 |

| Copper cyanide |

All |

100 |

No |

No |

| Ferric chloride |

All |

100 |

65 |

60 |

| Ferrous chloride |

All |

100 |

60 |

50 |

| Manganese sulfate |

All |

100 |

65 |

45 |

| Sodium cyanide |

All |

100 |

—— |

—— |

| Potassium nitrate |

All |

100 |

65 |

40 |

| Zinc sulfate |

All |

100 |

65 |

45 |

| potassium nitrate |

100 |

100 |

65 |

40 |

| Potassium dichromate |

100 |

100 |

60 |

40 |

| Ethylene glycol |

100 |

100 |

65 |

40 |

| Propylene glycol |

100 |

100 |

65 |

40 |

| Gasoline |

100 |

80 |

60 |

35 |

| Glucose |

100 |

100 |

38 |

No |

| Glycerin |

100 |

100 |

65 |

60 |

| Hydrogen peroxide |

30 |

38 |

— |

— |

| Dry chlorine gas |

100 |

82 |

38 |

No |

| Wet chlorine gas |

All |

82 |

No |

No |

| Vinegar |

100 |

100 |

65 |

30 |

| Distilled water |

100 |

93 |

60 |

25 |

| fresh water |

100 |

100 |

70 |

40 |

| Note: the “All” in concentration column refers to the chemical is saturated in water; and the “100” refers to pure chemicals. | ||||

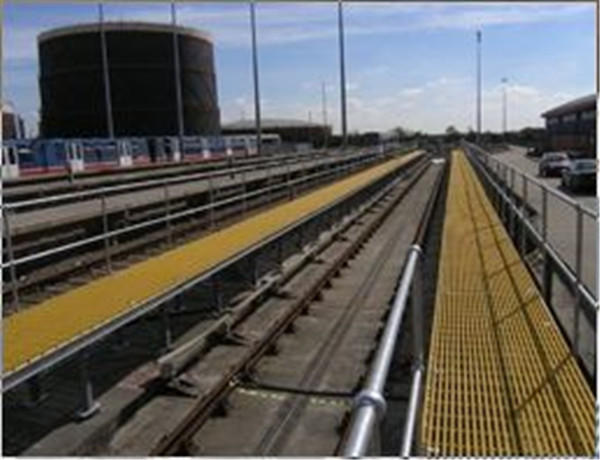

Product detail pictures:

Related Product Guide:

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for Manufacturer Of Cutting Fiberglass Grating - High Quality FRP GRP Pultruded Grating – WellGrid , The product will supply to all over the world, such as: India, Liberia, Benin, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.