Products

-

FRP Pultruded Profile

FRP Pultrusion production process is a continuous production process to produce fiber-reinforced polymer profiles of any length and constant section. Reinforcement fibers may be roving, continuous mat, woven roving, carbon or others. The fibers are impregnated with a polymer matrix (resin, minerals, pigments, additives) and passed through a pre-forming station that produces the stratification necessary to give the profile the desired properties. After the pre-forming step, the resin-impregnated fibers are pulled through a heated die to polymerize the resin.

-

frp molded grating

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Our product passes a whole series of well known third party tests with the fire and mechanical properties, and the product sells well all over the world and has a good reputation.

-

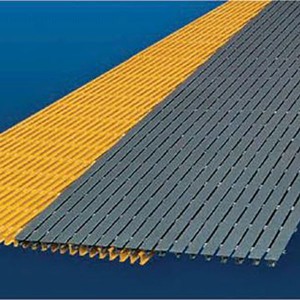

High Quality FRP GRP Pultruded Grating

FRP Pultruded Grating is assembled with pultruded I and T sections linked by cross rod per distance into a panel. The distance is decided by an open area rate. This grating has more fiberglass content compared to FRP Molded Grating, so it is stronger.

-

FRP Handrail System and BMC Parts

FRP Handrail is assembled with pultrusion profiles and FRP BMC parts; with the strong points of high strength, easy assembly, non rust, and maintenance free, the FRP Handrail becomes an ideal solution in bad environments.

-

Industrial Fixed FRP GRP Safety Ladder and Cage

FRP Ladder is assembled with pultrusion profiles and FRP Hand lay-up parts; the FRP Ladder becomes an ideal solution in bad environments, such as chemical plant, marine, out door.

-

FRP Anti Slip Nosing & Strip

FRP Anti Slip Nosing & Strip are capable of dealing with the busiest of environments. Manufactured from a fiberglass base it has been enhanced and strengthened by adding high grade vinyl ester resin coating. Finished with aluminium oxide grit finish provides an excellent slip resistant surface that will last for many years. Anti Slip Stair Nosing is manufactured from premium grade, slip-resistant fibreglass to maximise quality, durability and lifespan, plus it can easily be cut to any size. Not only does stair nosing add an extra anti-slip surface, but it can also highlight attention to the edge of a stair, which can often be missed in low lighting, particularly outdoors or in a poorly lit stairwell. All our FRP anti slip stair treads adhere to ISO 9001 standards and are made with premium-grade, slip and corrosion resistant fibreglass. Easy to install – simply glue and screw to timber, concrete, chequer plate steps or stairs.

-

HEAVY DUTY FRP Deck / Plank /Slab

FRP Deck (also called plank) is a one-piece pultruded profile, 500mm over width and 40mm thick, with a tongue and groove joint along the length of the plank that gives a firm, sealable joint between lengths of profile.

The FRP Deck gives a solid floor with a gritted anti-slip surface. It will span 1.5m at a design load of 5kN/m2 with a deflection limit of L/200 and meets all the requirements of BS 4592-4 Industrial type flooring and stair treads Part 5: Solid plates in metal and glass reinforced plastics (GRP) Specification and BS EN ISO 14122 part 2 – Safety of Machinery Permanent means of access to machinery.

-

Easy assembly FRP Anti Slip Stair Tread

Fiberglass stair treads is an essential complement to molded and pultruded grating installations. Designed to meet or exceed OSHA requirements and building code standards, fiberglass stair treads have below advantage:

Slip-resistant

Fire retardant

Non-conductive

Light Weight

Corrosion retardant

Low maintenance

Easily fabricated in the shop or field -

Easily installed FRP GRP Walkway Platform System

A FRP Walkway Platform not only reduces trips, slip and falls, it prevents walls, pipes, ducts and cables from being damaged. For a simple access solution, choose one of our FRP Walkway Platform and we’ll supply it fully fabricated and ready for you to install. We offer a range of sizes designed to clear obstacles up to 1000mm high with a span of up to 1500mm. Our Standard FRP Walkway Platform are constructed using Universal FRP Profiles, FRP Stair Tread, 38mm FRP Open Mesh Grating and continuous FRP handrail on both sides.

-

FRP Hand Layup Product

Hand layup method is the oldest FRP molding method for making FRP GRP composite products. It does not require technical skills and machinery. It’s a way of small volume and high labor intensity, especially suitable for large parts such as FRP vessel. Half of the mold is usually used during hand layup process.

The mold have the structural shapes of the FRP products. In order to make the product surface shiny or textured, the mold surface should have a corresponding surface finish. If the outer surface of the product is smooth, the product is made inside the female mold. Likewise, if the inside must be smooth, then molding is done on the male mold. The mold should be free of defects because the FRP product will form the mark of the corresponding defect.