Personlized Products Carbon Steel Grating Clip - frp molded grating – WellGrid

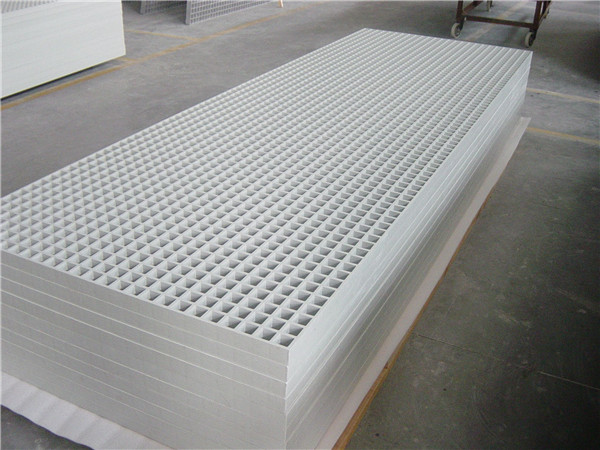

Personlized Products Carbon Steel Grating Clip - frp molded grating – WellGrid Detail:

Advantages

1. Corrosion Resistance

Different types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

2. Fire Resistance

Our special formula provide grating with excellent fire resistant performance. Our FRP gratings pass ASTM E-84 Class 1.

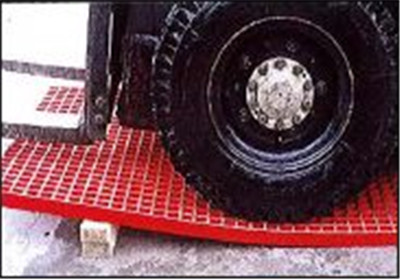

3. Light Weight & High Strength

The perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 1/4 of that of steel, 1/3 of aluminum. Its rigidity is up to and even exceeds that of steel. Different thickness and mesh size bring the client more choice.

4. Safety & Anti-slip

The high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

5. Electrical Insulating

High strength E-glass roving and high-grade resin provide the product super electric performance. Its electric break strength could reach 10KV/mm. There is no electric spark even when impact by tools, meanwhile it is non-magnetism. FRP Molded Grating could be used safely under the antiknock, diamagnetism and electric-resistance environments.

6. Aging Resistance

The high-grade resin and anti-ageing stabilizer provide grating long-life ageing resistant performance and the unique design make grating excellent self-cleanness function and keep its brightness and strength over a long time. The service life of grating could be 25 years.

FRP Molded Grating Availability

|

No. |

Deep mm |

Mesh Size mm |

Panel Size Available mm (Width * Length) |

Open Area % |

Unit Weight (kg/m2) |

|

1 |

13 |

38*38 |

1220*3660 |

68 |

6.3 |

|

2 |

13 |

50*50 |

1220*3660 |

78 |

5.8 |

|

3 |

13 |

38*38+19*19 |

1220*3660 |

40 |

10.8 |

|

4 |

14 |

40*40+20*20 |

1007*4047 |

42 |

10.5 |

|

5 |

22 |

40*40+20*20 |

1007*4047 |

42 |

15.0 |

|

6 |

25 |

38*38 |

1220*3660/1000*4038 |

68 |

12.7 |

|

7 |

25 |

38*38+19*19 |

1220*3660 |

40 |

16.6 |

|

8 |

25 |

40*40 |

1007*4047 |

66 |

12.5 |

|

9 |

25 |

100*25 |

1007*3007 |

66 |

13.0 |

|

10 |

25 |

101.6*25.4 |

1220*3660 |

64 |

15.2 |

|

11 |

30 |

38*38 |

1220*3660/1000*4038 |

68 |

15.0 |

|

12 |

30 |

38*38+19*19 |

1220*3660/1000*4038 |

40 |

18.6 |

|

13 |

30 |

40*40+20*20 |

1007*4047 |

42 |

18.0 |

|

14 |

30 |

38*38+12*12*12 |

1220*3660/1000*4038 |

30 |

22.0 |

|

15P |

38 |

38*38 |

1525*3050/1220*3660/1000*4038 |

68 |

19.0 |

|

16 |

38 |

38*38+19*19 |

1220*3660/1000*4038 |

40 |

23.7 |

|

17 |

38 |

40*40+20*20 |

1007*4047 |

42 |

23.5 |

|

18 |

38 |

38*152 |

1220*3660 |

66 |

19.0 |

|

19 |

40 |

40*40 |

1007*4047 |

66 |

20.0 |

|

20 |

50 |

38*38 |

1220*3660 |

56 |

42.0 |

|

21 |

50 |

50*50 |

1220*3660 |

78 |

21.2 |

|

22 |

60 |

38*38 |

1220*3660 |

54 |

51.5 |

| Notes: the letter P following the No. means this grating could be supplied with phenolic resin. | |||||

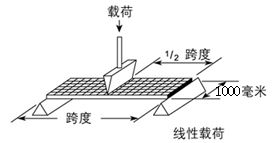

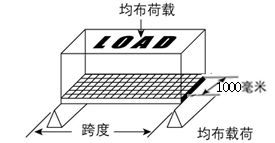

RP Molded Grating Loading Table

25mm 38x38mm

30mm 38x38mm

38mm 38x38mm

50mm 50x50mm

25mm 38x38mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

600 |

750 |

||

|

450 |

0.559 |

1.146 |

2.159 |

3.073 |

4.115 |

4.75 |

3910 |

|

600 |

0.864 |

1.702 |

3.505 |

5.156 |

6.706 |

8.173 |

2924 |

|

900 |

2.896 |

5.918 |

12.116 |

18.44 |

—— |

—— |

1948 |

|

1200 |

5.715 |

11.633 |

—— |

—— |

—— |

—— |

1461 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

240 |

480 |

980 |

1450 |

2450 |

3650 |

||

|

450 |

0.66 |

1.092 |

1.93 |

2.769 |

4.47 |

6.579 |

—— |

|

600 |

1.118 |

2.108 |

4.14 |

6.172 |

10.211 |

15.265 |

—— |

|

750 |

3.667 |

5.387 |

10.82 |

16.28 |

—— |

—— |

—— |

|

900 |

5.537 |

11.176 |

21.717 |

—— |

—— |

—— |

—— |

30mm 38x38mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

750 |

1500 |

||

|

300 |

<0.254 |

<0.254 |

0.254 |

0.508 |

0.762 |

1.524 |

9923 |

|

450 |

0.254 |

0.508 |

1.106 |

1.524 |

2.54 |

—— |

4828 |

|

600 |

0.508 |

1.27 |

2.286 |

3.556 |

5.842 |

—— |

4112 |

|

750 |

1.27 |

2.54 |

4.826 |

7.366 |

12.446 |

—— |

3174 |

|

900 |

1.778 |

3.81 |

7.62 |

11.43 |

—— |

—— |

2637 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

350 |

500 |

750 |

1000 |

1500 |

2500 |

||

|

300 |

<0.254 |

<0.254 |

<0.254 |

<0.254 |

0.254 |

0.508 |

32501 |

|

450 |

0.254 |

0.508 |

0.762 |

1.106 |

1.524 |

2.286 |

21661 |

|

600 |

1.016 |

1.524 |

2.286 |

2.794 |

4.318 |

7.366 |

12981 |

|

750 |

2.54 |

3.81 |

5.842 |

7.62 |

11.684 |

—— |

8396 |

|

900 |

4.572 |

7.112 |

10.668 |

—— |

—— |

—— |

5758 |

38mm 38x38mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

600 |

750 |

||

|

300 |

0.279 |

0.356 |

0.483 |

0.61 |

0.762 |

0.889 |

17116 |

|

600 |

0.356 |

0.66 |

1.245 |

1.85 |

2.464 |

3.073 |

8718 |

|

900 |

0.864 |

1.803 |

3.683 |

5.563 |

7.417 |

9.296 |

5817 |

|

1200 |

2.261 |

4.749 |

9.677 |

14.63 |

19.583 |

—— |

3755 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

240 |

480 |

980 |

1450 |

2450 |

3650 |

||

|

300 |

0.254 |

0.305 |

0.381 |

0.457 |

0.635 |

0.838 |

—— |

|

600 |

0.432 |

0.813 |

1.549 |

2.311 |

3.8354 |

5.74 |

—— |

|

900 |

1.702 |

3.454 |

6.959 |

10.465 |

17.475 |

—— |

—— |

|

1200 |

5.969 |

12.167 |

24.511 |

—— |

—— |

—— |

—— |

50mm 50x50mm

|

Span mm |

Concentrated Line Load (kg/m) |

Max Load |

|||||

|

75 |

150 |

300 |

450 |

600 |

750 |

||

|

300 |

0.279 |

0.305 |

0.406 |

0.483 |

0.635 |

1.041 |

21727 |

|

600 |

0.356 |

0.508 |

0.813 |

1.128 |

1.753 |

3.327 |

11713 |

|

900 |

0.508 |

1.118 |

2.235 |

3.2 |

5.156 |

10.058 |

7780 |

|

1200 |

0.914 |

1.93 |

3.937 |

5.918 |

9.957 |

—— |

5834 |

|

Span mm |

Uniform Load (kg/m2) |

Max Load |

|||||

|

240 |

480 |

980 |

1450 |

2450 |

3650 |

||

|

300 |

0.254 |

0.279 |

0.33 |

0.381 |

0.483 |

0.737 |

—— |

|

600 |

0.381 |

0.584 |

0.965 |

1.372 |

2.134 |

4.115 |

—— |

|

900 |

1.194 |

2.108 |

3.937 |

5.766 |

9.449 |

18.593 |

—— |

|

1200 |

2.413 |

4.928 |

9.954 |

14.961 |

—— |

—— |

—— |

RP Molded Grating Loading Table

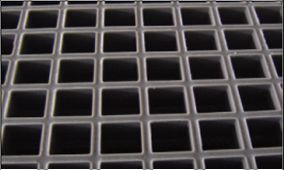

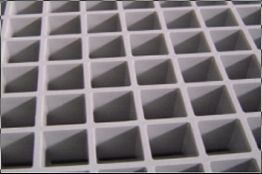

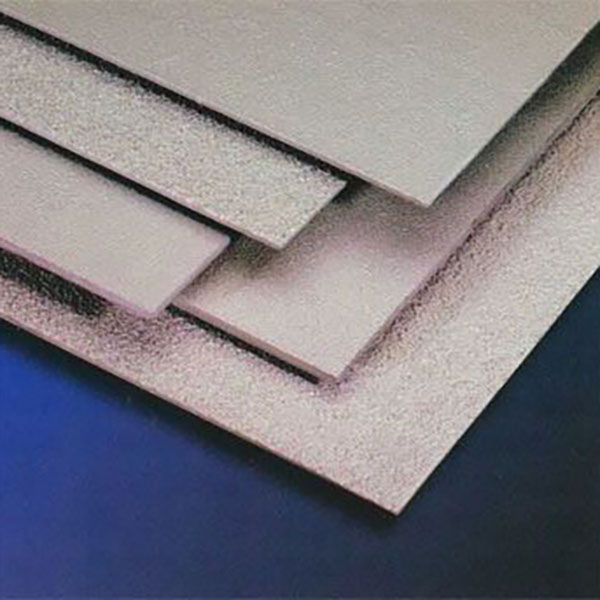

|

Real |

Surface |

Service |

|

Concave surface |

Anti-skid, easy clean |

|

|

Grit surface |

Anti-skid and good abrasion (The grit could be fine, middle and coarse) |

|

|

Smooth surface |

Free clean, contaminant non stay |

|

|

Chequer cover surface |

Anti-skid, easy clean, odour isolation |

|

|

Grit cover surface |

Anti-skid, good abrasion (The grit could be fine, middle and coarse), odour isolation |

Standard Resin Systems

|

ONFR |

Polyester resin system, Good corrosion resistance, Non fire resistance; |

|

OFR |

Polyester resin system, Good corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

ISOFR |

Premium grade Isophthalic Polyester resin system, excellent corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

VEFR |

Vinyl Ester resin system, Maximum corrosion resistance, Fire resistance ASTM E-84 Class 1; |

|

PHE |

Phenolic resin system, High temperature service, Low flame spread index, low smoke developed index and low toxicity. |

Chemical Properties

FRP Molded Grating Chemical Properties Guide

|

Chemicals |

Concentration |

Maximum service temperature |

||

|

Vinyl ester resin |

Iso resin |

Ortho resin |

||

| Acetic acid |

50 |

82 |

30 |

20 |

| Chromic acid |

20 |

38 |

No |

No |

| Nitric acid |

5 |

70 |

48 |

25 |

| Phosphoric acid |

85 |

100 |

65 |

No |

| Sulfuric acid |

25 |

100 |

52 |

20 |

| Hydrochloric acid |

<10 |

100 |

52 |

No |

|

20 |

90 |

38 |

No |

|

|

37 |

65 |

No |

No |

|

| Hydrotropic acid |

25 |

93 |

38 |

No |

| Lactic acid |

100 |

100 |

52 |

40 |

| Benzoic acid |

All |

100 |

65 |

—— |

| Aluminum hydroxide |

All |

82 |

45 |

No |

| Aqueous ammonia |

28 |

52 |

30 |

No |

| Sodium hydroxide |

10 |

65 |

20 |

No |

|

25 |

65 |

No |

No |

|

|

50 |

70 |

No |

No |

|

| Ammonium sulfate |

All |

100 |

60 |

50 |

| Ammonium chloride |

All |

100 |

82 |

60 |

| Ammonium bicarbonate |

All |

52 |

No |

No |

| Copper chloride |

All |

100 |

65 |

60 |

| Copper cyanide |

All |

100 |

No |

No |

| Ferric chloride |

All |

100 |

65 |

60 |

| Ferrous chloride |

All |

100 |

60 |

50 |

| Manganese sulfate |

All |

100 |

65 |

45 |

| Sodium cyanide |

All |

100 |

—— |

—— |

| Potassium nitrate |

All |

100 |

65 |

40 |

| Zinc sulfate |

All |

100 |

65 |

45 |

| potassium nitrate |

100 |

100 |

65 |

40 |

| Potassium dichromate |

100 |

100 |

60 |

40 |

| Ethylene glycol |

100 |

100 |

65 |

40 |

| Propylene glycol |

100 |

100 |

65 |

40 |

| Gasoline |

100 |

80 |

60 |

35 |

| Glucose |

100 |

100 |

38 |

No |

| Glycerin |

100 |

100 |

65 |

60 |

| Hydrogen peroxide |

30 |

38 |

— |

— |

| Dry chlorine gas |

100 |

82 |

38 |

No |

| Wet chlorine gas |

All |

82 |

No |

No |

| Vinegar |

100 |

100 |

65 |

30 |

| Distilled water |

100 |

93 |

60 |

25 |

| fresh water |

100 |

100 |

70 |

40 |

| Note: the “All” in concentration column refers to the chemical is saturated in water; and the “100” refers to pure chemicals. | ||||

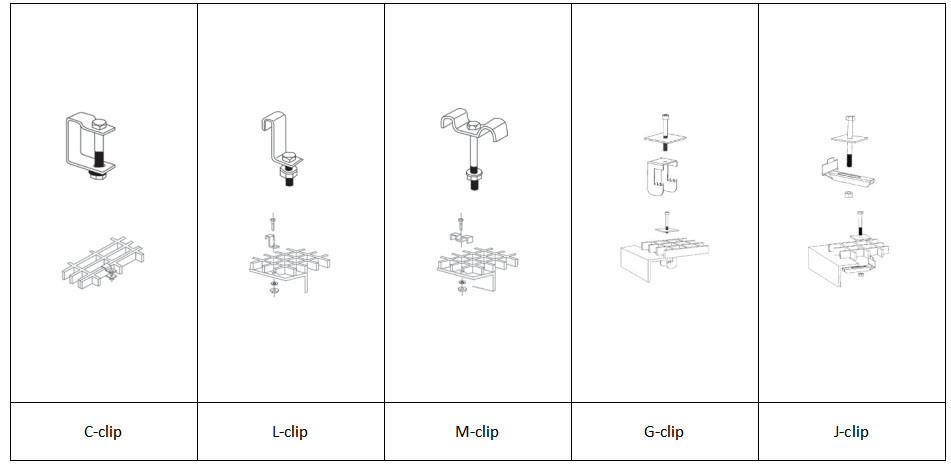

Hold down Clips: Stainless steel holds down clips are one of our services to our clients.

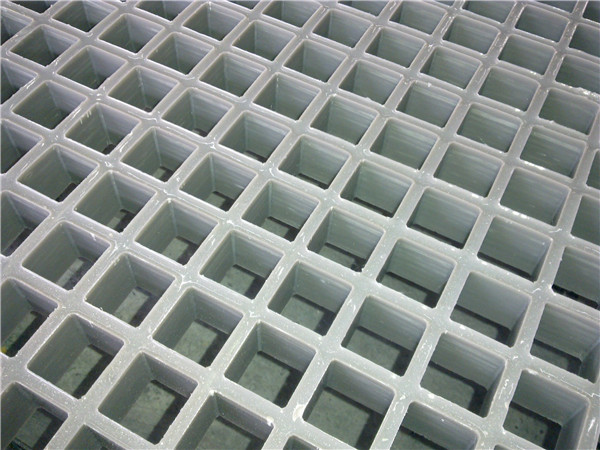

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Personlized Products Carbon Steel Grating Clip - frp molded grating – WellGrid , The product will supply to all over the world, such as: Iran, Bahrain, Jordan, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!